Calibration of Gauge Block Comparators EURAMET

calibration of gauge block comparators are given. The second part of this guideline is of procedural nature and gives practical advice to calibration laboratories. In sections 5 and 6 an example of a typical calibration procedure is presented. It is noted that laboratories working according to ISO/IEC 17025 shall validate their calibration

Free Caliper Calibration Procedure Sample Ape Software

The purpose of this procedure is to provide general instructions for the calibration of calipers including dial, vernier, digital, or a combination thereof. Scope All calipers used to measure, gage, test, inspect and control part compliance to customer specifications and drawings.

Alco Sensor IV Calibration Procedure Intoximeters

Locate the calibration tool in the carrying case of your Alco Sensor IV. The calibration tool is a small plastic peg. During the calibration procedure, the calibration tool will be used to depress the calibration switches. The switches should be pressed gently to avoid

Alco Sensor IV Calibration Procedure Intoximeters

Locate the calibration tool in the carrying case of your Alco Sensor IV. The calibration tool is a small plastic peg. During the calibration procedure, the calibration tool will be used to depress the calibration switches. The switches should be pressed gently

Calibration of measuring instruments WIKA

Calibration instruments for the calibration of measuring instruments. With the calibration instruments for temperature, calibration of your temperature measuring instrument is possible in the range of 200 +1,300 °C (control range 55 +1,100 °C). In our product portfolio of calibration instruments for electrical measurands you can find,

Electrical Calibration Equipment Fluke Calibration

Electrical calibration refers to the process of verifying the performance of, or adjusting, any instrument that measures or tests electrical parameters. This discipline is usually referred to as dc and low frequency electrical metrology. Principal parameters include voltage, current, resistance, inductance, capacitance, time and frequency.

High Precision Reference Multimeter Fluke Calibration

The MET/CAL™ Calibration Management Software advantage. The 8588A and 8558A work with Fluke Calibration MET/CAL™ Calibration Software, in 8508A emulation mode, allowing increased throughput while ensuring calibrations are performed consistently every time. This powerful software documents calibration procedures, processes and results for ease in complying with ISO/IEC 17025 and similar

Electrical Test Equipment Electrical Calibration Equipment

Transmille provide electrical calibration equipment for different services, helping your electric tester needs with our electrical test equipment.

New Alco Sensor III Calibration Procedure Intoximeters

New Alco Sensor III Calibration Procedure. Prior to calibrating an Intoximeters breath alcohol testing instrument, you should be trained to perform the calibration functions as allowed under your specific testing program. The calibration procedures below are designed to

Calibration Procedures, Articles & Education Fluke Cal

Access calibration procedures, articles, videos & other education. Which calibration procedure is right for you? Learn that plus more calibration education here Articles and Education. General Calibration / Metrology Topics » Terms of Sale

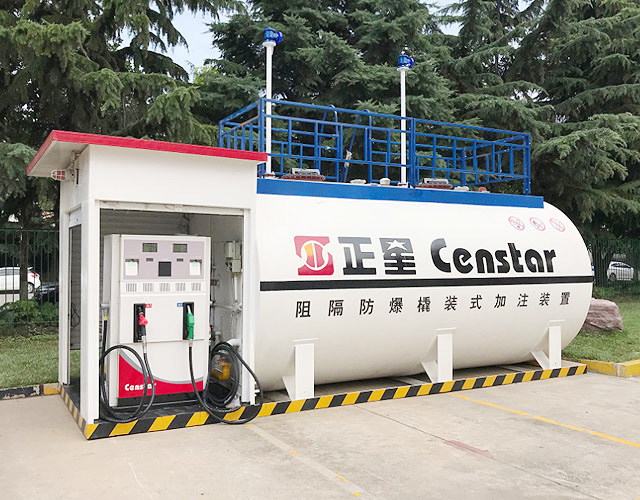

Calibration Procedures, Oscilloscope Tektronix Type 547 Censtar

See more Calibration Procedures Oscilloscope Tektronix Email to friends Share on Facebook opens in a new window or tab Share on Twitter opens in a new window or tab Share on Pinterest opens in a new window or tab.

Weighing scale calibration How to calibrate weighing

The calibration procedure should specify where to place the load during the test and calibration results (in certificate format) should also document the locations. The test load used in an eccentricity test should be at least one third (1/3) of the max load of the weighing instrument.

Procedure for Equipment Calibration and Maintenance

Procedure for Equipment Calibration and Maintenance. 1.0 Purpose This procedure specifies the schedule and requirements for calibration, performance verification, and maintenance of State Crime Laboratory testing instruments and equipment. 2.0 Scope This procedure applies to the critical laboratory equipment used by the Laboratory.

Micrometer Calibration Standard Sets

Starrett 1 to 5 Inch Long, 5 Piece Micrometer Calibration Standard Set For Use with Outside Micrometer, Includes Case, Redemption Card for SLC Your Price: $ ea.

Sample Calibration Procedure Presentationeze

1.1. This sample calibration procedure defines the calibration program requirements for all Measurement and Test Equipment (MTE). 2.0 Scope 2.1. Measurement and Test Equipment are those devices used to test, measure, evaluate, inspect, or otherwise examine materials, supplies, equipment, and systems, or to determine compliance with specifications. 2.2.

Calibration Procedures NIST

Calibration Procedures. However, the organization of the sections and procedures on this and linked pages follows the format of the original Handbook 145, Table of Contents. Individual sections and procedures are provided to enable periodic updates of selected content as needed and to provide downloadable copy for laboratories to review, modify,

ADAS Sensor Calibration Increases Repair Costs AAA

Finally, sensor calibration is necessary when there is a related DTC in the car’s computer memory, or an automaker releases a technical service bulletin with instructions that calibration be done as part of another repair. Sensor replacement and calibration are frequently part of collision repairs.

New Alco Sensor III Calibration Procedure Intoximeters

New Alco Sensor III Calibration Procedure. Prior to calibrating an Intoximeters breath alcohol testing instrument, you should be trained to perform the calibration functions as allowed under your specific testing program. The calibration procedures below are designed to help you ensure precise and accurate test results.

How to Perform Pressure Gauge Calibration with a Dead

Procedure for Calibrating a Pressure Gauge with a DWT. To check the full range of the pressure gauge, repeat these 7 steps with increasing sample weights, till you reach the test device’s maximum pressure. Then, reverse the order of weights and record the downscale readings till the test device reaches 0 again.

RADIATION DETECTORS CALIBRATION NIST

Step by Step Calibration Procedures. Procedures for calibrations using three instruments are described: (1) small area counter, (2) large area counter, and (3) external counter. At the completion of measurements and calculations, results are entered into a spreadsheet.

Message

Message tel

tel Inquiry

Inquiry